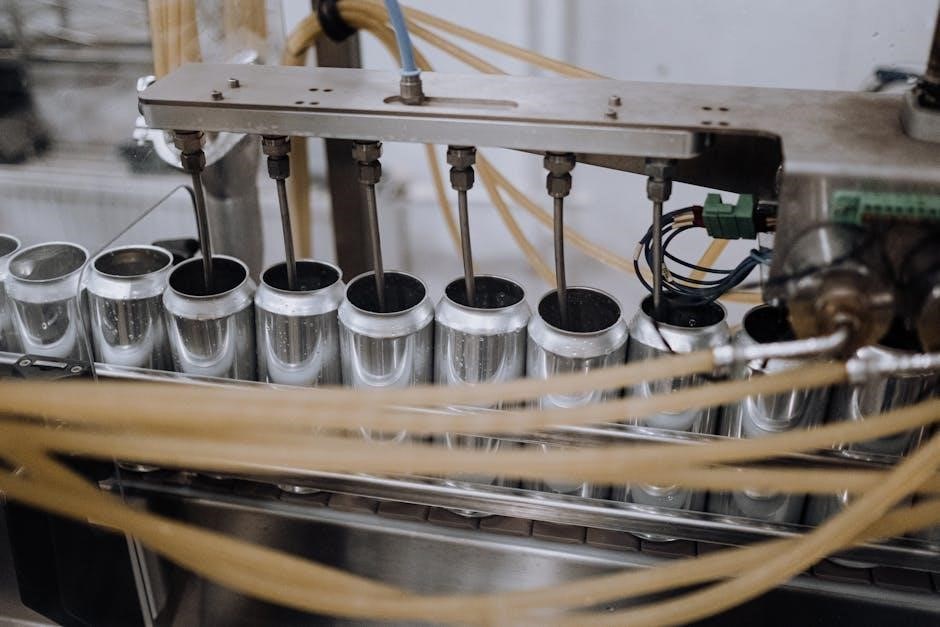

manual bottle filling equipment

Manual bottle filling equipment is essential for efficiently transferring liquids into bottles. Ideal for small-scale production or personal use, it offers simplicity and cost-effectiveness compared to automatic systems. This equipment provides precise control and minimizes waste, making it a practical choice for various bottling needs.

Types of Manual Bottle Filling Equipment

Manual bottle filling equipment includes piston fillers, gravity fillers, and siphon fillers. Each type is designed for specific applications, offering versatility and ease of use. They cater to different liquid viscosities and bottling requirements, ensuring efficient filling processes.

2.1 Subtypes Based on Liquid Type

Manual bottle filling equipment can be categorized into subtypes based on the liquid type they handle. For instance, there are fillers designed specifically for water, oils, and viscous liquids like syrups or honey. Each subtype incorporates unique design features to accommodate the properties of the liquid. For example, equipment for viscous liquids often includes heated components to reduce thickness, ensuring smooth flow. On the other hand, fillers for foamy liquids, such as beer or soda, are equipped with mechanisms to minimize frothing during the filling process. Additionally, there are specialized fillers for corrosive or hazardous liquids, featuring resistant materials to prevent damage; These subtypes ensure optimal performance and accuracy for different liquid characteristics, making manual filling equipment versatile for various industries. By selecting the right subtype, users can achieve efficient and precise bottle filling tailored to their specific needs.

2.2 Subtypes Based on Bottle Size

Manual bottle filling equipment also varies based on the size of the bottles it is designed to accommodate. For smaller bottles, such as miniature or sample-sized containers, compact and lightweight fillers are ideal. These are often portable and easy to handle, making them suitable for limited production runs or laboratory settings. On the other hand, larger bottles, like those used for industrial or bulk liquids, require sturdier and more robust fillers. These models typically feature extended nozzles or adjustable height settings to reach the bottom of tall containers. Additionally, some equipment is designed specifically for wide-mouth bottles, incorporating broader filling nozzles to ensure quick and efficient filling. The design of the filler often includes features like adjustable spouts or handles to accommodate different bottle sizes, ensuring versatility and ease of use; This categorization helps users select equipment that best fits their bottling needs, optimizing both efficiency and convenience.

How Manual Bottle Filling Equipment Works

Manual bottle filling equipment operates through a straightforward process that relies on user interaction to transfer liquids into bottles. The equipment typically consists of a filling mechanism, a control system, and a container for holding the liquid. To begin, the user places the bottle under the filling nozzle or spout. Depending on the design, the user may activate the flow of liquid by pressing a lever, turning a handle, or squeezing a trigger. This action opens a valve or releases the liquid from the storage container into the bottle. The user then monitors the filling process, stopping it once the desired level is reached. Some models may include features like adjustable flow rates or measuring markers to ensure accuracy. After filling, the user seals the bottle and repeats the process for the next one. This manual operation allows for precise control over the filling process, making it suitable for small-scale or specialized bottling needs.

Advantages of Manual Bottle Filling Equipment

Manual bottle filling equipment offers several advantages, making it a popular choice for various applications. Its cost-effectiveness is a significant benefit, as it requires a lower initial investment compared to automated systems. Additionally, manual equipment is highly portable, allowing users to easily move it between locations. The simplicity of its design ensures minimal maintenance and fewer mechanical issues, reducing downtime and operational costs. It also provides precise control over the filling process, enabling users to fill bottles accurately without excess waste; Manual systems are ideal for small-scale production or specialty bottling, where flexibility and adaptability are key. Furthermore, they are environmentally friendly, as they consume less energy and reduce reliance on automated machinery. These advantages make manual bottle filling equipment a practical and efficient solution for businesses and individuals seeking reliable, hands-on bottling solutions.

Disadvantages of Manual Bottle Filling Equipment

Manual bottle filling equipment, while practical for small-scale operations, has several drawbacks. The process is labor-intensive, requiring constant human intervention, which can lead to operator fatigue and physical strain. This reliance on manual effort makes it less efficient for large production volumes, limiting scalability. Additionally, there’s potential for inconsistency in fill levels due to human variability. Unlike automated systems, manual filling is generally slower, which can be a disadvantage in time-sensitive environments. Furthermore, the risk of human error is higher, potentially resulting in overfilling or underfilling bottles and causing product waste. These factors make manual bottle filling equipment less suitable for high-output industries and applications where precision and speed are critical.

Applications Across Various Industries

Manual bottle filling equipment is widely used across various industries due to its versatility and adaptability. In the food and beverage sector, it is commonly employed for small-batch production, such as craft breweries, wineries, and specialty drink manufacturers. The cosmetics industry utilizes manual fillers for packaging creams, serums, and other personal care products, where precision and cleanliness are paramount. Pharmaceutical companies often rely on manual systems for filling small batches of ointments, lotions, or medications. Additionally, households and small businesses use this equipment for homemade products like oils, sauces, and cleaning solutions. Laboratories and research facilities also benefit from manual fillers for handling small volumes of samples or chemicals. Its simplicity and cost-effectiveness make it a preferred choice for industries requiring low to moderate production volumes, ensuring efficient and accurate filling processes.

Tips for Choosing the Right Manual Filling Equipment

Selecting the right manual bottle filling equipment requires careful consideration of several factors; First, determine the type of liquid you will be filling, as viscosity and consistency can affect equipment performance. Consider the production volume and desired filling speed to ensure the equipment meets your needs without unnecessary complexity. Measure the bottle sizes and shapes you plan to use, as some fillers are designed for specific bottle types. Assess the ease of use and ergonomics to minimize operator fatigue during extended use. Durability and material quality are crucial for long-term reliability, especially in environments requiring frequent cleaning. Look for adjustable features, such as fill levels and nozzle types, to accommodate varying bottle sizes and liquid types. Additionally, evaluate the cost and compare it to your budget, ensuring the equipment offers good value for its price. Finally, consider customer support and warranty options to address any potential issues or maintenance needs.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the optimal performance and longevity of manual bottle filling equipment. Start by cleaning the equipment thoroughly after each use to prevent residue buildup and contamination. Lubricate moving parts periodically to reduce wear and tear. Inspect hoses, seals, and nozzles for signs of damage or wear, replacing them as needed to avoid leaks and inaccuracies. Store the equipment in a dry, clean environment when not in use to prevent rust or degradation. For troubleshooting common issues, check for clogs in the filling nozzle or tubes, which can be cleared with a soft brush or by soaking in warm water. If the equipment is not filling bottles evenly, adjust the fill level or ensure the bottle is properly aligned. Addressing these issues promptly can prevent downtime and maintain efficiency. Always refer to the manufacturer’s guidelines for specific maintenance and troubleshooting recommendations tailored to your equipment model.

Safety Precautions When Using Manual Filling Equipment

Using manual bottle filling equipment requires attention to safety to prevent accidents and ensure smooth operations. Always wear protective gear, such as gloves and goggles, to shield yourself from potential spills or broken glass. Ensure the equipment is placed on a stable, even surface to avoid tipping. Before use, inspect the equipment for any damage, such as cracks or worn-out seals, which could lead to leaks or inconsistent filling. Keep loose clothing or long hair tied back to avoid entanglement with moving parts. When handling heavy bottles, lift with care to prevent strain or drops. Work in a well-ventilated area, especially when dealing with volatile liquids, to avoid inhaling fumes. Follow the manufacturer’s guidelines for operating pressures and liquid types to prevent overfilling or equipment damage. In case of spills, have a cleanup kit nearby to contain and dispose of the liquid safely. Lastly, never leave the equipment unattended while in use, and ensure proper training is provided to all operators.

Best Practices for Effective Use

To maximize efficiency and longevity when using manual bottle filling equipment, adhere to best practices. Begin by calibrating the equipment according to the manufacturer’s instructions to ensure accurate filling volumes. Always prepare the workspace by cleaning and drying it to prevent contamination. Use bottles of appropriate size and type for the liquid being filled to avoid overflow or underfilling. Follow the recommended filling speed to maintain control and reduce spillage. Regularly inspect and clean the equipment to prevent residue buildup and maintain hygiene. After each use, wipe down surfaces and store the equipment in a dry, secure location. Train all operators on proper techniques to minimize errors and extend equipment lifespan. Keep spare parts and maintenance tools on hand for quick repairs. Finally, organize bottles and supplies in an accessible manner to streamline the filling process. By following these guidelines, you can ensure safe, efficient, and consistent performance from your manual bottle filling equipment.

Manual bottle filling equipment offers a practical and cost-effective solution for bottling needs across various industries. Its simplicity, precision, and versatility make it an ideal choice for small-scale productions, startups, and even large enterprises seeking flexibility. By understanding the types, operation, and maintenance requirements, users can optimize their bottling processes. While it may lack the speed of automated systems, manual equipment excels in scenarios requiring customization and control. Proper care, regular maintenance, and adherence to safety guidelines ensure longevity and efficiency. For businesses or individuals looking for a reliable, adaptable, and user-friendly bottling solution, manual filling equipment remains a valuable and indispensable tool. Its enduring relevance underscores its importance in meeting diverse bottling demands effectively.